Differential thermal analysis: temperature under program control, the relationship and difference of temperature between the measured material and the reference.

The DTA curves is to describe the changing relationship depending on temperature and time between the measured material and the reference compound. During the test, the sample temperature changes due to the phase change or an endothermic or exothermic reaction effects. For example: the phase transition, melting, changing the crystal structure, boiling, sublimation, evaporation, dehydrogenation, cracking or decomposition reaction of oxidation or reduction reaction, destroy the lattice structure.

Technical parameters:

| Temperature range | room temperature ~ 1200ºC |

| Measure Range | 0 ~ ± 2000μV |

| DTA Accuracy | ± 0.1μV |

| Heating rate | 1 ~ 80 ºC / min |

| Temperature Resolution | 0.1 ºC |

| Temperature accuracy | ± 0.1 ºC |

| Temperature Repeatability | ± 0.1 ºC |

| Temperature control | Heating : process control parameters can be adjusted |

| Cooling : air-cooled process control | |

| Thermostat : Programmable thermostats, can be set | |

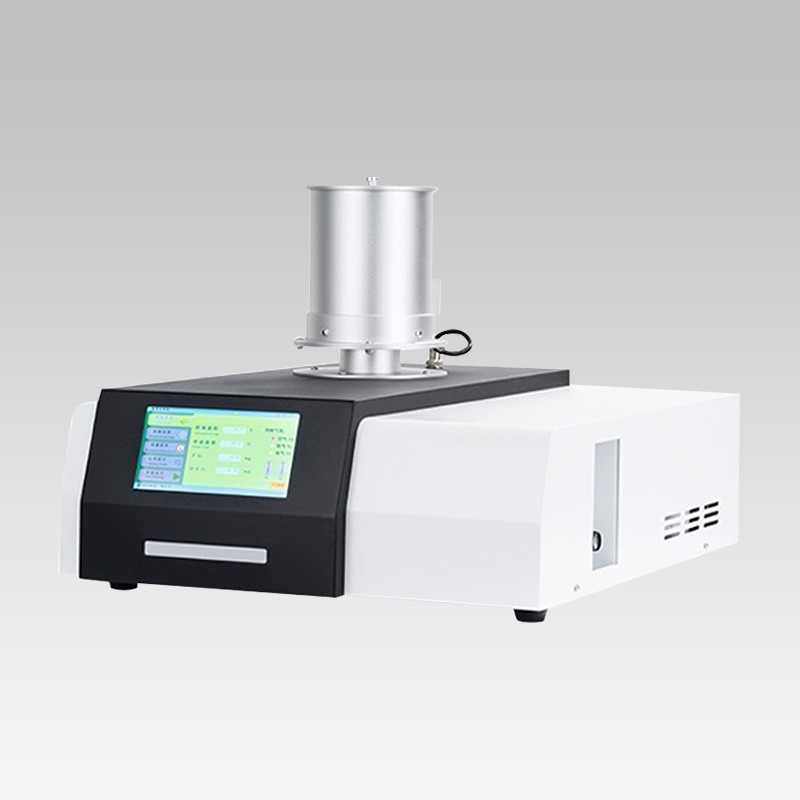

| Furnace | With the lid, instead of the traditional lift furnace |

| Air-flow | gas flow meter ( Optional) , the atmosphere converter |

| Data interface | standard USB interface cable and operating software |

| Display | 24bit color 7-inch LCD touch- screen display |

| Parameter Standard | With calibration function, can calibrate the temperature |

| Baseline Adjustment | Users can adjust by baseline slope and intercept |

| Power | AC 220V 50Hz |